Vi giver dig det nyeste indenfor robotteknologi, styring og servosystemer. Vælg mellem et bredt udvalg af produkter og ydelser der både er innovative og skalérbare. Vi udvikler helhedsløsninger på dine vilkår.

MOTOMAN Robot Controllers

YRC1000

Powerful and multi-functional Robot Controller

Overview

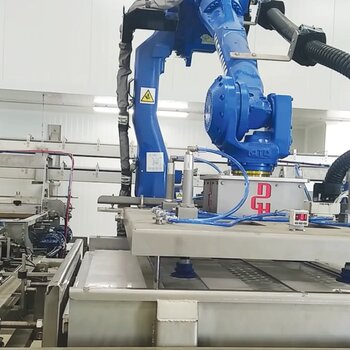

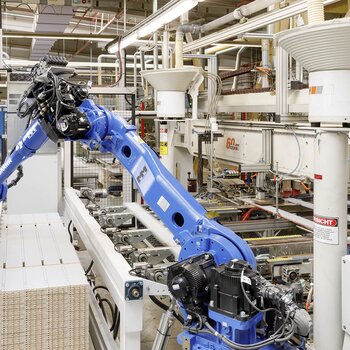

The MOTOMAN YRC1000 is a compact and powerful multi axis and multi tasking controller platform for robots and peripheral motion, like positioners, tracks and gantries, coordinating motion of up to 8 robots (Master/Slave) and additional external axes up to a total of 72 motion axes. it can be used with all GP-Series handling and spot welding robots, AR-Series arc welding robots, HC-Series cobots, HD-Series robots with Hygienic Design and PL-Series Palletizers.

Operation

Typically, the YRC1000 comes with a standard Teach Pendant (touch screen) for professional users, or the intuitive Smart Pendant, for users starting their journey into robotics. The operation concept of MOTOMAN robots has been evolved and optimized over the years, based on the experience and feedback of more than 500.000 robots installed in the field so far, resulting in a today's highly efficient operating and programming environment with simple and easy-to-learn flat hierarchy menu structures, hotkeys, quick takeover of teach positions and understandable program structures with simple line based statements. Using the powerful, high level language Inform III, specialists can user powerful commands, make excessive use of control logioc or even create sophisticated motion or communication functions or drivers on their own. User right management is based on a modern USB Stick system.

Motion Control Technology

A very fast multitasking CPU, an advanced operating system and the superior Yaskawa Sigma7 high speed servo technology allow high accelerations, fast axis speeds and superior path performance.

The multitasking, non-Windows-based operating system with very fast interpolation cycle does not require virus protection (saving the associated high update/maintenance efforts). The boot time is <40 sec. Thanks to very fast interpolation cycles, all MOTOMAN robots provide excellent path performance. The Advanced Robot Motion (ARM) function dynamically calculates and controls the torque and load of the robot axes, optimises acceleration and speed, eliminates vibrations, adjusts target positions very quickly and enables highly sensitive collision detection. Different interpolation methods, path switching functions and position level control allow precise definition and execution of the robot path. An integrated, very fast soft PLC that is closely interacting with the robot program I/Os can be used to control peripherals or smaller production cells and can potentially make a PLC cell controller obsolete in simple installations.

Controller Hardware

In case of repair, all components can be quickly exchanged (MTTR < 5 min). The compact, industry-proof, stackable controller cabinet (IP54) has an indirect cooling system and is ideally suited for rough industrial environments. Each robot cabinet (Master or Slave) offers installation space for up to 3 external axis controllers. A modular system of 3 different cabinet sizes offer enough space to integrate more external axes, interfaces and connectors, fieldbus and safety systems, PLC cell control systems or 3rd party application controllers.

Functions and Function Packages (Hardware/Software)

The YRC1000 offers a variety of function packages (standard, extended, advanced), application specific Function packages (General, Handling, Arc Welding, Spot Welding, Paint), single functions (e.g. Servofloat, Machine Vision, Analog Control) and syntax extensions, all of them making programming and commissioning of MOTOMAN robots and their peripheral comfortable and easy.

Machine Safety (MSU/FSU)

The YRC1000 has a two channel safety system architecture (MSU, Emergency Stop and Safety Signals for safe I/O communication, and an onboard dual channel Functional Safety Board (FSU). Safety devices like Safety Scanners or light barrier can be wired directly to the controller. All Teach Pendants provide the obligatory 3 position enabling switches. All robot servo motors are using high precision absolute encoders and spring operated brakes which are closed in the event of an emergency stop - there is no need for cyclical brake tests.

Functional Safety (FSU) Software Options

The Functional Safety Software deploys the features of the FSU unit, providing options to allow safe moniting of position and speed inside/outside of defined workspace zones (axis ranges, cartesian zones, virtual curtains or protection zones around a tool). The FSU supports definition of a large number of these zones, allowing to model even complex cells layouts or interactions. The FSU considers the complete mechanical structure of the robot including elbows, not only the TCP (Tool Center Point), and allows to model the robot tooling and workpiece, including all these elements into the safe monitoring. The FSU is a powerful tool to reduce installation space, create safe interference zones, and - in case of collaborative robot installations - helping to achieve reasonably good cycle times even in collaborative mode.

Energy Efficiency and CO2-Footprint

With the latest YASKAWA Sigma7 Generation Servo Drive Generation, Yaskawa achieved to increase the energy efficiency of MOTOMAN robots significantly. Other Energy Saving Options, e.g. „Individual Servo-Off“, are available. As a standard, YRC1000 controllers for larger MOTOMAN robot models are equipped with a condensator-based recuperation unit, leading to a significant energy recovery rate specifically in applications of short motion sequences and many decelerations like spot welding.

Open Communication

The YRC1000 can be easily integrated into existing networks. The robot controller comes with a set of standard communication interfaces, e.g. two Ethernet ports or digital inputs/outputs, as well as the FTP-capable TCP/IP web server function, allowing to read/set the controller status or enabling remote monitoring or maintenance over the Web. Other digital and analog I/O communication boards are available. The YRC1000 supports interfaces and communication protocols for the Digital Factory / Industry 4.0, e.g. OPC/UA (supporting the VDMA Robotics Companion Specification).

As a worldwide robot manufacturer, Yaskawa supports a unique variety of fieldbus systems, such as Profinet, Devicenet, ASI-Bus, Profibus, EthernetIP, ModbusTCP, CCLink, EtherCAT including their safety bus variants, as well as market-specific interfaces such as Euromap or Varan. Direct or fieldbus-based communication interfaces are available for a big variety of peripheral devices and equipment, often combined with a HMI integration on the teach pendant, e.g. supporting different weld controllers, grippers, 2D/3D Vision Systems or Force/Torque Sensors.

Open Programming

MOTOMAN Robots with YRC1000 controllers are open for many programming methods, each of them making sense in their individual applications, markets or environments, such as:

- Hand Guiding (only collaborative HC Series robots)

- Standard Teach Pendant (Touchscreen), highly functional and menu/command-line based (Inform III)

- the intuitive, easy-to-use Smart Pendant

- Motologix Function Blocks, embedding robot programming completely in commonly used IEC 61131-based PLC programming environments

- Software Pendant (PC based)

- Offline-Simulationstool MotoSimVRC (OLP) (Device, Cell & Line Level)

- 3rd party Offline-Simulationstools (OLP) (Cell / Line / Plant Simulation Level) and Digital Twin Solutions

- Application related Apps and wizards (e.g. Welding Wizard, PalletSolver, Motologix)

- 3rd party CAD/CAM-Tools (deriving robot code from CAD Data over G-Code post processors)

- Robot Operating System ROS

- 3rd party, cross brand robot programming environments

- API-Interfacing to Scientific PC Programming environments, e.g. Matlab oder LabView

- 2D/2D Machine Vision control, Bin Picking, feature or AI/Neural network based

- Hardware Programming Devices like Teach Pens or gloves

- Customer developed apps, wizards, visualisations, HMIs, coded by using our Software Development Kits (e.g. Motoplus C/C++, MotoCom32 SDKs)

Downloads

| Name | |||

|

Flyer Controller YRC1000

Industrial Robot Controller Data sheet | engelsk |

Data sheet | engelsk | |

|

Flyer Steuerung YRC1000

Industrieroboter-Steuerung für MOTOMAN-Roboter Data sheet | tysk |

Data sheet | tysk | |

|

Flyer FunctionalSafetyUnit FSU

Improved Safety Functions with integrated Safety Controller Data sheet | engelsk |

Data sheet | engelsk | |

|

Flyer FunktionaleSicherheitssteuerung FSU

Verbesserte Sicherheitsfunktionen mit integrierter Sicherheitssteuerung Data sheet | tysk |

Data sheet | tysk | |

| YRC1000 Cabinets 2D CAD/CAE | | CAD/CAE | ||

| YRC1000 Cabinets 3D CAD/CAE | | CAD/CAE | ||

| YRC1000 Master Cabinet 2D CAD/CAE | | CAD/CAE | ||

| YRC1000 Master Cabinet 3D CAD/CAE | | CAD/CAE | ||

| Functions Packages YRC1000 Brochures | engelsk | Brochures | engelsk | |

| Functions Packages YRC1000 Brochures | tysk | Brochures | tysk | |

| Flyer Externe Antriebsachsenpakete Brochures | tysk | Brochures | tysk | |

| Flyer External Drive Axis Packages Brochures | engelsk | Brochures | engelsk |